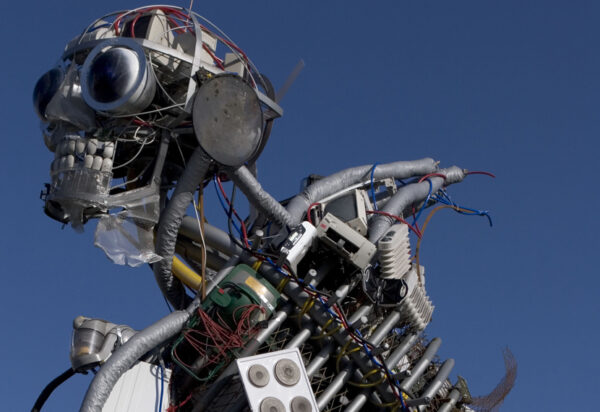

Innovation is often described as a two-headed monster. Theoretical research leads to solutions in search of a problem. Conversely, applied research seeks solutions to existing real-world problems. However, there is a third approach which is perhaps best described as ‘lateral innovation’. Innovating laterally involves taking existing and established platforms and using them in new ways.

Some call it ‘hacking’, but that is perhaps to do the process a disservice.

Over the last few weeks we’ve been exploring how we might use a lighting desk (a long established and ubiquitous control console) to control stepper motors that are regularly used to drive kinetic sculptures. There has been an element of demand-led development; not all clients want to implement a Qmotion control surface, and if they are able to control kinetic devices with their existing hardware, then the cost of implementation can be reduced and the training period accelerated.

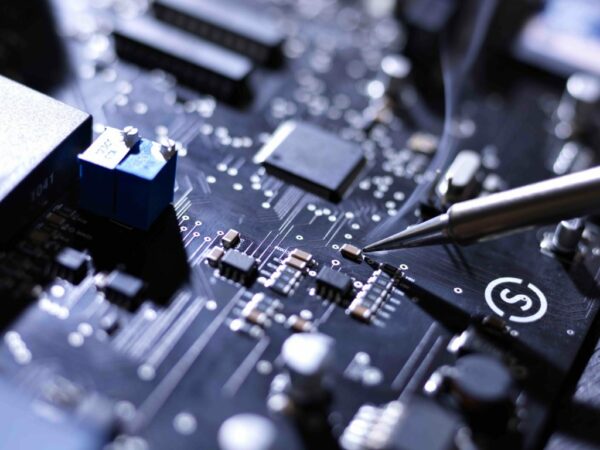

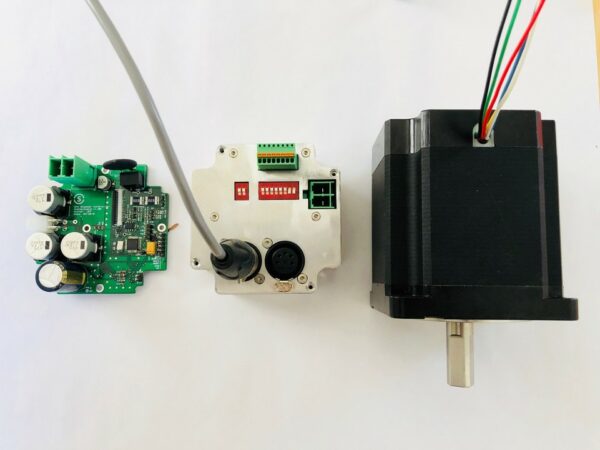

Consequently, we’ve designed and prototyped a printed circuit board that will take a DMX output from a lighting desk and use this to provide positional control over a stepper motor. The familiar sliders on the desk can then be used to give fine control over the vertical position of an axis within an array.

The firmware for the unit is written in embedded C using a realtime operating system running on an ARM microprocessor, giving us a robust and proven platform for development. We’ve machined a housing from aluminium and this will neatly locate on the rear of the stepper motor. It’s a smart solution and one that we’ve developed and prototyped in just a matter of weeks. It’s fast, robust and really simple to implement.

Currently this set up is aimed at smaller scale implementations that require small to moderate sized motors.

However, in principle, there is no reason why we couldn’t develop this to work across large scale devices.

So, does this signal the end of our Qmotion software? Absolutely not. Qmotion continues to develop and will always remain at the heart of our automation control offering. However, by providing alternative ways to interface and control mechanical equipment we make our broader technical offering stronger than ever.

If you’d like to learn more, get in touch. We’re always happy to share our developments in more detail with you.