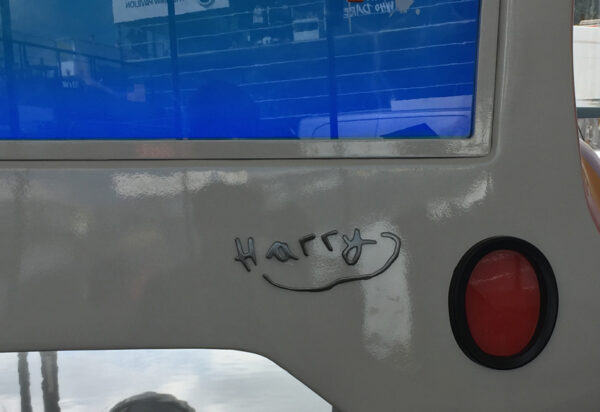

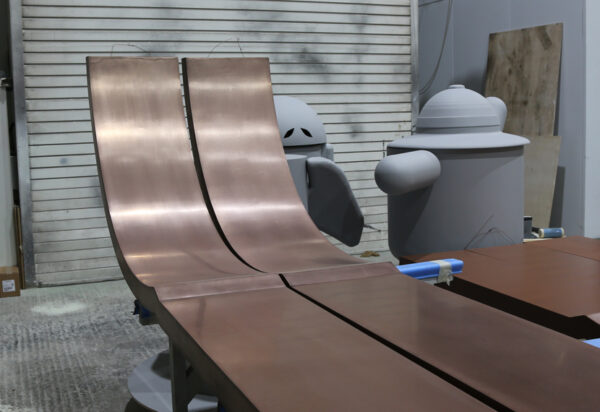

There isn’t much this team don’t know about High Quality finishes. And what they don’t know, they’ll research and experiment, producing samples to ensure that each project has the exact finish required. They’re a small, highly skilled team with experience that ranges from high-spec exterior finishes for architectural panels to stylised trees for an event; from automotive bodywork to trains for a theme park ride. They work with a wide range of materials too, including metals, fibreglass, GRP, plastics and MDF.

Providing a rigorously clean, dust-free environment for the preparation, application and curing of finishes is imperative. Our Finishing Team have dedicated spray booths, temperature-controlled curing ovens and even a separate metalwork priming paint shop at their disposal. Thanks to our three aircraft hangars of workshops, they also have a lot of space – an extremely useful resource when working on projects that require a HQ finish on hundreds of panels or components.

When it comes to paint, our Pro-spray paint mixing centre allows our team to create highly specific paints to order. It’s a computerised system that means we can offer a staggering 60,000 colours in-house, providing high-speed and accurate colour matching in project specific quantities.