-

The Hive

Wolfgang Buttress View -

Ed Sheeran Mathematics

Hayagotatourboi View -

Serpentine Pavilions

2009-2022 View -

Johnnie Walker Experience

BRC Imagination Arts View -

Cloud Cities

Tomás Saraceno View -

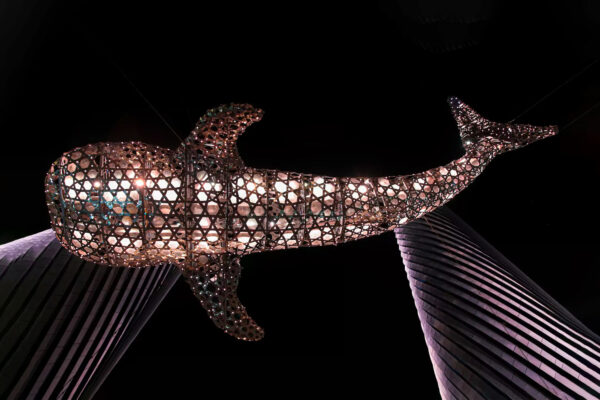

UAE National Day 49

Larmac Live View

WE ARE STAGE ONE

We take big ideas and turn them into unforgettable experiences

Stage One is a creative manufacturing and engineering company that delivers high-end projects for the creative industries. From ceremonies and live events to entertainment and architecture, our work creates moments that people remember for ever.

- CEREMONIES

- ARTWORKS & INSTALLATIONS

- EXPERIMENTAL ARCHITECTURE

- ENVIRONMENTS & EXPERIENCES

- MUSIC & ENTERTAINMENT

We operate at the intersection of design, engineering & technology

Our multidisciplinary in-house team are proficient in high-end paint finishes, precision metal work and intricate joinery. We deliver high-spec manufacturing and installation and will support you throughout the life cycle of your project.

Mailer sign up

Mailer sign up

If you're interested in our work and want to keep up to date with our latest projects, sign up to our mailing list. We'll keep in contact throughout the year, sharing our achievements and learnings as we continue to deliver projects across the globe.

Filter

No results

We are proud of our projects. Explore our extensive back-catalogue and see just how far the company has come.

Results